Nuclear Instruments and Methods in Physics Research B 268, 3269 (2010)

AFM characterization of model nuclear fuel oxide multilayer structures

modified by heavy ion beam irradiation

M.E. Hawley*, D.J. Devlin, C.J. Reichhardt, K.E. Sickafus, I.O. Usov,

J.A. Valdez, and Y.Q. Wang

Materials Science and Technology Division, Los Alamos National Laboratory, Los Alamos, New Mexico 87545, USA

ARTICLE INFO

Article history:

Received 9 October 2009

Received in revised form 2 June 2010

Available online 9 June 2010

Keywords:

Metal oxide films

Radiation effects

Heavy ions

Atomic force microscopy

Surface modification

Abstract

This work explored a potential new model dispersion fuel form

consisting of an actinide material embedded in a radiation tolerant

matrix that captures fission products (FPs) and is easily separated chemically

as waste from the fuel material. To understand the stability of this proposed

dispersion fuel form design,

an idealized model system composed of a multilayer film was studied. This system

consisted of a tri-layer

structure of an MgO layer sandwiched between two HfO2 layers.

HfO2 served as a surrogate fissile material for

UO2 while MgO represented a stable, fissile product (FP)

getter that is easily separated from the

fissile material. This type of multilayer film structure allowed us to control the

size of and spacing

between each layer. The films were grown at room temperature by e-beam

deposition on a Si(1 1 1) substrate and post-annealed annealing at a range

of temperatures to crystallize the HfO2 layers. The 550°C

annealed sample was subsequently irradiated with 10 MeV Au 3+

ions at a range of fluences from 5 × 1013

to 3.74 × 1016 ions/cm2 .

Separate single layer constituent films and the substrate were also irradiated at

5 × 1015 and 8 × 1014

and 2 × 1016, respectively.

After annealing and irradiation, the samples were characterized

using atomic force imaging techniques to determine local changes in microstructure and

mechanical properties. All samples annealed above 550 °C cracked.

From the AFM results we observed

both crack healing and significant modification of the surface at higher fluences.

1. Introduction

2. Experiment

3. Results

References

1. Introduction

New composite dispersion fuel designs consisting of an actinide

material imbedded in a radiation tolerant matrix are being explored

to fill three critical needs: containment of fission products

(FP), easy separation of FPs from spent nuclear fuel, and greater energy

production [1].

To understand the stability of this proposed

fuel form design under radiation conditions, idealized model systems

were studied. In this study, a tri-layer oxide film structure

was chosen to represent this potential model fuel. This type of

structure allowed us to control the size of each layer, which represented

the size of each component and the spacing between repeat

layers.

The tri-layer film structure used in this work consisted of a thick

layer (880 nm) of a surrogate fissile material sandwiched between

two thinner layers (50 nm) of a radiation stable metal oxide matrix

material [2].

The matrix material's role is to capture and accumulate

the FPs and be easy to separate chemically from the fissile

material. In this case, HfO2 was chosen to serve as surrogate fissile

material for UO2 . Although MgO is known to experience void swelling

under irradiation [2],

it was selected as the matrix material

partly because it can be removed from the sample in acidic solutions

where its rate of dissolution is dependent on factors such

as acid concentration, MgO grain size, and temperature

[3]. The

choice of these relatively simple oxides was also to facilitate the

modeling effort, not covered in this paper. The films were

post-deposition annealed to crystallize the HfO2 layers, which is

amorphous when deposited at room temperature. The onset of

the crystallization to the monoclinic phase of HfO2 starts around

500 °C and is fully developed by about 800°

[4, 5,

6]. (1 1 1)-oriented

MgO grows on Si(1 1 1) at room temperature

[7], however, grown

on the HfO2 layer or the SiO2 native oxide layer the film is

polycrystalline.

The stability of the tri-layer film structure was tested by bombarding

the samples in a flux of heavy ions at relatively high energies

(10 MeV) and fluences (up to 4 × 1016). At these energies both

nuclear and electronic stopping is expected. Resulting changes in

topography, crystal structure, defects generation, interface mixing,

and layer thickness were characterized using a suite of tools

including Atomic Force Microscopy (AFM, also referred to a Scanning

Force or Scanning Probe Microscopy) results presented here.

AFM contributes nanometer to micron scale three-dimensional

information, which includes changes in grain size and structure,

surface roughness, surface morphology, and local variations in

nano mechanical properties. The latter is achieved by monitoring

changes in the oscillatory behavior of the cantilever probe as it

scans across and in contact with the sample surface.

2. Experiment

Tri-layer films consisting of a 50 nm base layer of HfO2 , an 800

to 880 nm layer of MgO, and a 50 nm top layer of HfO2 were grown

at room temperature by e-beam deposition on 4 00 Si(1 1 1) substrates.

The room temperature growth resulted in a polycrystalline

layer of MgO separating two amorphous HfO2 layers. These thicknesses

were chosen to represent the desired relative separation

and quantity of the surrogate fissile material and the radiation tolerant

material needed to trap the FPs. The substrates were used as

received with a native oxide layer of about 2 nm [8].

After deposition, the wafer was cleaved into smaller pieces, which were then

annealed in air for 12 h at temperatures between 200 °C and

1000 °C to determine the affect of annealing temperature on the

film's microstructure and the crystallization of the HfO2 layers.

The 550 °C substrate piece was further divided into pieces for a

fluence-dependent irradiation study. These pieces were irradiated

with 10 MeV Au 3+ ions in the Ion Beam Materials Laboratory at

Los Alamos National Laboratory at fluences ranging from 5 ×

1013 to 5 × 1016 ions/cm2

using a DanFysik 20 kV high current

ion implanter [9].

Single-phase films of the two component materials, MgO and

HfO2, were irradiated at 5 × 1015 ions/cm2

and

pieces of the bare substrate were irradiated at 8 × 1014

and 2 × 1016 ions/cm2

for comparison with the irradiated tri-layer samples.

3. Results

The as-grown tri-layer film was relatively smooth (RMS =

7.3 nm), with 20 to 30 nm grains randomly oriented on the surface.

For the annealed films, no increase in RMS roughness was observed

until 800 °C, where the beginning of faceting of some of the grains

was seen in the capping HfO2 layer. However, even at the lowest

annealing temperature, the grains had begun to coalescence into

larger aggregates. All samples annealed above 500 °C had interconnected

cracks in a dried mud pattern and, at the highest temperature,

pieces of the film delaminated from the substrate.

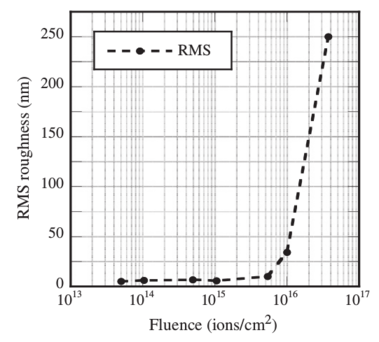

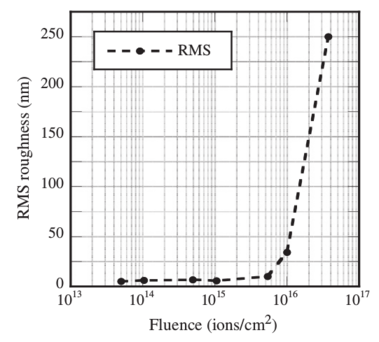

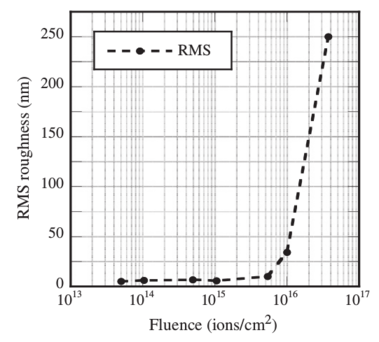

Figure 1:

Plot of RMS surface roughness as a function of fluence for the 550 °C

annealed films irradiated with 10 MeV Au 3+ ions.

Figure 1:

Plot of RMS surface roughness as a function of fluence for the 550 °C

annealed films irradiated with 10 MeV Au 3+ ions.

|

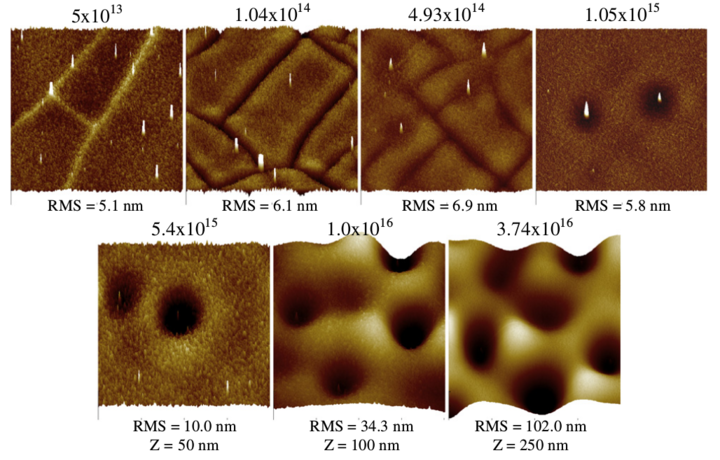

After irradiation, the AFM results revealed a roughing of the surface

(shown in Fig. 1), increase in crack density, crack healing, and

finally significant modification as the fluence increased (Fig. 2).

Initially at the lowest fluences the crack density increased and the

crack profile inverted. At 1 × 1014 ions/cm2,

the edges of the cracks

became rounded out-of-plane. At ~5 × 1014 ions/cm2

not only was

the crack density greater, the edge rounding increased and depressions

in the surface containing a central peak appeared. When the

fluence was increased to 1 × 1015 ions/cm2

the cracks disappeared,

at least at the surface. The round depressions or craters were

deeper and the central peaks more prominent. Note that these

depressions are large (8-12 μ m in diameter) and possess well-defined

ridges. The craters at all fluences were non-uniformly distributed

across the sample surfaces. Interestingly, the height of its

central peak did not correlate with the depth of its crater, that is

very tall peaks were observed in both deep and shallow craters.

Likewise relatively short peaks were found in deep craters. Further

increase in fluence resulted in an increased density and deepening

of the craters, although their diameters remained approximately

the same. Even though the average depth of the craters did increased

with fluence, there was variation in depth between craters

on the same sample. At the highest density of craters, the ridges

that defined their perimeters were no longer distinguishable and

the RMS roughness increased to 20 times that of the sample irradiated

at the lowest fluence. It is also important to note that the

depth of the craters at the three highest fluences exceeded the

50 nm thickness of the top HfO2 layer. At the highest fluence some

of the craters were over 400 nm deep, i.e. 8 times the thickness of

that layer.

Figure 2:

40 × 40 μm AFM profile images of the 550 °C annealed tri-layer

films surface as a function of fluence. Note: the vertical

scale for the two highest fluences is 100 and

250 nm compared to 50 nm for the rest of the images.

Figure 2:

40 × 40 μm AFM profile images of the 550 °C annealed tri-layer

films surface as a function of fluence. Note: the vertical

scale for the two highest fluences is 100 and

250 nm compared to 50 nm for the rest of the images.

|

At intermediate fluences, the central peaks in the craters often

protrude above the surface, extending as much as 150 to 300 nm

from the base of the crater. Their measured contact angles ranged

from around 6 to 8 degrees up to nearly 30 degrees, depending on

the peak height.

Phase imaging revealed local changes in nano mechanical properties

as well. The peaks and the areas surrounding the craters appear

"softer" in the phase image than the base of the crater

suggesting compositional variations across the surface. This is consistent

with a non-uniform loss of HfO2 from the top layer observed

in TEM cross sectional data (not presented here).

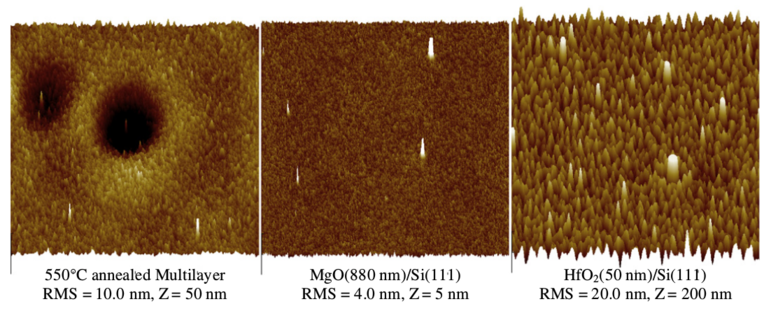

Figure 3:

40 × 40 μm AFM images showing a comparison of the surface modification

of the 550C annealed tri-layer film, a single MgO layer, and a single HfO2

layer after

irradiation with 5 × 1015 ions/cm2

10 MeV Au 3+ ions. Note the differences in RMS roughness and z vertical scales.

The single layer films are the same thickness as in the tri-layer film.

Figure 3:

40 × 40 μm AFM images showing a comparison of the surface modification

of the 550C annealed tri-layer film, a single MgO layer, and a single HfO2

layer after

irradiation with 5 × 1015 ions/cm2

10 MeV Au 3+ ions. Note the differences in RMS roughness and z vertical scales.

The single layer films are the same thickness as in the tri-layer film.

|

A comparison of the radiation tolerance toward surface modification

of the individual components of the tri-layer is shown in

Fig. 3. Although there was a change in the grain structure of the

MgO film, the RMS roughness did not increase after irradiation.

However, this was not the case for the HfO2 film, where the RMS

roughness increased at least 10-fold. However, even with this large

increase in roughness after irradiation, no craters were formed;

they were only observed on the tri-layer sample.

One final observation, a couple of AFM phase images and local

surface potential measurements (not shown), which were used to

try to determine if subsurface cracks persisted as the fluence was

increase, did reveal their existence but not in which layer, MgO

or the bottom HfO2 layer, or if they disappeared at the highest

fluences.

4. Discussion

Figure 4:

Plots of the coefficient of linear thermal expansion as a function of

temperature for MgO and HfO2

[10],

and Si [11]. The left black line marks the

deposition T, while the right is approximately 550 °C.

Figure 4:

Plots of the coefficient of linear thermal expansion as a function of

temperature for MgO and HfO2

[10],

and Si [11]. The left black line marks the

deposition T, while the right is approximately 550 °C.

|

In order to understand the origin of cracking in the films annealed above

500 °C (753 K) one has to identify the probable origins.

The first factor is the different thermal responses of the

components that make up the tri-layer film and their substrate,

the largest component. Fig. 4 presents plots of the linear thermal

expansion coefficients, α, for MgO, HfO2, and silicon as a function

of temperature in degrees K over the relevant temperature range

used in the annealing process

[10,

11]. The black line on the left

indicates the deposition temperature. The one on the right indicates

the temperature where cracking was first observed. Clear

from this figure is the increasing disparity in the linear thermal

expansion properties between MgO and HfO2 and the silicon substrate.

At the film growth temperature MgO and silicon have similar values for

α. However, by 550 °C (823 K) the MgO value is

double that of the substrate. The situation is even worse when

you compare the value for HfO2 against MgO at that temperature.

The factor is almost 8 times greater for MgO than HfO2 .

The second potential candidate for driving cracking is the

change in volume of the HfO2 layers, particularly the trapped

bottom layer, during the transformation from an amorphous phase

to the monoclinic crystalline phase. Crystallization of HfO2 is

observed to begin around 500 °C and continue up to

800 °C [4,

5,

6],

the temperature at which crystallites were observed in the AFM

images. In addition, non-uniform crystallization at 550 °C would

lead to non-uniform strain in the films. Both factors could also induce cracking.

The situation is further complicated if heating the

polycrystalline MgO layer lead to further crystal growth.

The increase in number of cracks at the lower fluences could reduce

strain and aid dewetting between the MgO and HfO2 layers,

especially if these materials have significantly different surface

energies. Accurate measurement of the contact angle at the crack

edges are needed to help resolve this issue. However, the inversion

of the crack edge to form rounded, raised ridges increasing with

fluence is consistent with a dewetting mechanism.

The sudden onset of crack healing, at least in the top HfO2 layer,

when the fluence was doubled from 5 × 1014

to 1 × 1015 ions/cm2

and the formation of craters with a central peak is harder to explain

but appears to suggest a complicated intersection between

competing mechanisms, dewetting and a non-uniform strain field.

The non-uniform distribution of craters and crater sizes is consistent

with a variation in forces driven by non-uniform structure

and strain distribution.

The large size of the craters, increase in surface roughness, and

appearance of a central peak, which often extends above the surface,

does not point to a simple mechanism, especially if one considers

that the depth of craters is larger than the thickness of the

original top HfO2 layer and approaches a large fraction of the

tri-layer thickness. These dimensions require the loss or movement

of a significant proportion of both materials in the tri-layer. Phase

images also suggest that the inside of the crater wall is different

from the central peak and surrounding surface material and could

be a different phase. The lack of correlation between the crater

depth and the central peak height might also point to their formation

being decoupled in some way.

Irradiated of single-phase films of the two materials did not in

either case result in the formation of these unusual structures.

These experiments revealed totally different damage resistance.

Little change except in grain size was seen in the MgO film. In contrast

the HfO2 surface roughness increased 10 times. Since neither

formed craters with central peaks, this observation further points

to non-uniform strain and dewetting mechanisms in the tri-layer

structure grown on silicon.

We believe this is the first observation of crack healing and the

formation of large circular craters with central peaks in these

materials. The author could find no reference documenting the

appearance of radiation induced large, 8 to 12 μm diameter, craters

with central peaks protruding above the surface. Modeling efforts

are under way to understand the mechanisms behind both the

crack healing and the formation of the surface structures observed

by AFM techniques.

Acknowledgment

This work was supported by a Los Alamos National Laboratory,

Laboratory Directed Research and Development (LDRD) Grant.

References

- [1]

-

G.D. Jarvinen, D.W. Carroll, D.J. Devlin, United States Patent Application

No. S-100, (2004) 559.

- [2]

-

K.E. Sickafus, L. Minervini, R.W. Grimes, J.A. Valdez, M. Ishimaru, F. Li,

K.J. McClellan, T. Hartmann, Science 289 (5480) (2000) 748.

- [3]

-

P. Raschman, A. Fedorockoa, Chem. Eng. J. 117 (2006) 205.

- [4]

-

S. Nam, S.W. Nam, J.H. Yoo, and D.-H. Ko, Mat. Res. Soc. Symp. Proc.

716 B4.25.1 (2002).

- [5]

-

H. Wang, Y. Wang, J. Feng, C. Ye, B.Y. Wang, H.B. Wang, Q. Li,

Y. Jang, A.P. Huang, Z.S. Xiao, Appl. Phys. A 93 (2008) 681.

- [6]

-

G. He, M. Liu, L.Q. Zhu, M. Chang, Q. Fang, L.D. Zhang, Surf. Sci. 576 (2005) 67.

- [7]

-

T.L. Chen, X.M. Li, X. Zhang, W.D. Yu, X.D. Gao, Proc. of SPIE 5774 (2004) 361.

- [8]

-

J.H. Mazur, R. Gronsky, and J. Washburn, Solid-State Phys. 37, page unknown (1983).

- [9]

-

I.O. Usov, J.A. Valdez, J. Won, M. Hawley, D.J. Devlin, R.M. Dicerson, B.P. Uberuaga,

Y.Q. Wang, C.J. Reichhardt, G.D. Jarvinen, K.E. Sickafus, Nucl. Instrum.

Meth. Phys. Res. B 267 (2009) 1918.

- [10]

-

Y.S. Touloukian, R.K. Kirby, et al. (Eds.), Thermal Expansion - Metallic Elements

and Alloys. Thermophysical Properties of Matter: The TPRC Data Series, IFI/Plenum,

New York, 1975.

- [11]

-

H. Watanabe, N. Yamada, M. Okaji, Int. J. Thermophysics 25 (1) (2004) 221.

File translated from

TEX

by

TTHgold,

version 4.00.

Back to Home