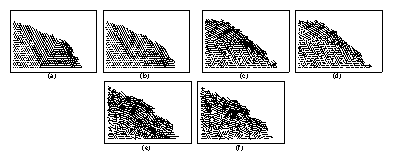

Figure 3: Dynamic images of granular collapse from simulation

at pairs of consecutive time intervals after the

right wall of the container has been removed. Circles indicate the

location of individual grain elements, light lines indicate bonds for

dimers and trimers, and heavier lines indicate the trajectories over a

short time of the individual grain elements. (a,b) Monomers, showing

orderly flow along lattice vector directions of large triangular wedges.

(c,d) Dimers, showing tumbling flow along the top surface of the pile

only. (e,f) Trimers, showing disorderly flow throughout the bulk,

with tumbling motion at the top of the pile.

Figure 3: Dynamic images of granular collapse from simulation

at pairs of consecutive time intervals after the

right wall of the container has been removed. Circles indicate the

location of individual grain elements, light lines indicate bonds for

dimers and trimers, and heavier lines indicate the trajectories over a

short time of the individual grain elements. (a,b) Monomers, showing

orderly flow along lattice vector directions of large triangular wedges.

(c,d) Dimers, showing tumbling flow along the top surface of the pile

only. (e,f) Trimers, showing disorderly flow throughout the bulk,

with tumbling motion at the top of the pile.

|