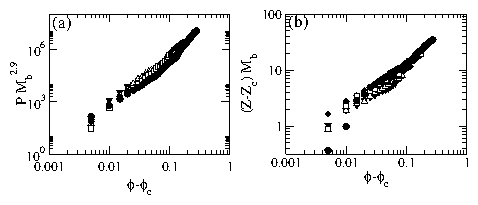

Figure 3:

(a) Scaling of pressure vs density,

P Mb2.9 vs ϕ−ϕc close to the jamming transition for

chains of length

Mb=6 (black down triangle),

8 (big up triangle),

10 (black lozenge),

16 (square),

and 24 (•).

(b)

Scaling of (Z−Zc) Mb vs ϕ−ϕc for chains of length

Mb=6, 8, 10, 16, and 24, with the same symbols as in panel (a).

Figure 3:

(a) Scaling of pressure vs density,

P Mb2.9 vs ϕ−ϕc close to the jamming transition for

chains of length

Mb=6 (black down triangle),

8 (big up triangle),

10 (black lozenge),

16 (square),

and 24 (•).

(b)

Scaling of (Z−Zc) Mb vs ϕ−ϕc for chains of length

Mb=6, 8, 10, 16, and 24, with the same symbols as in panel (a).

|