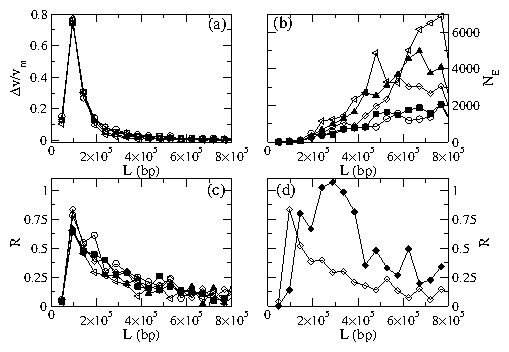

Figure 7:

(a) Selectivity ∆V/Vm from the system in Fig. 6(a)

versus polymer length L for fp=60

and ρp=0.8 at

FE= 37.88 (circles), 39.0 (squares), 40.12 (diamonds),

41.24 (triangle up), and 42.36 (triangle left).

(b) Efficiency NE for the same system at

FE= 37.88 (open circles), 39.0 (filled squares), 40.12 (diamonds),

41.24 (filled triangle up), and 42.36 (triangle left).

(c) Resolution R for the same system at

FE= 37.88 (open circles), 39.0 (filled squares), 40.12 (diamonds),

41.24 (filled triangle up), and 42.36 (triangle left).

(d) Resolution at FE= 40.12 for: (open diamonds)

the system in Fig. 6(a) and

(filled diamonds) the system in Fig. 6(b) where the polymers

were allowed to travel a longer distance.

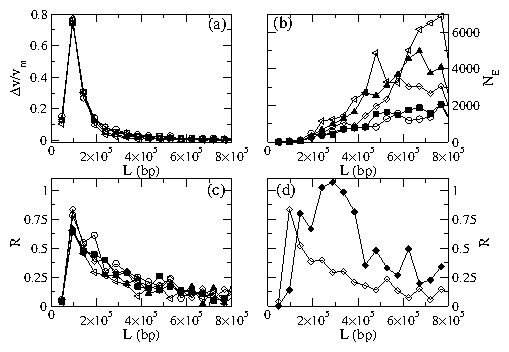

Figure 7:

(a) Selectivity ∆V/Vm from the system in Fig. 6(a)

versus polymer length L for fp=60

and ρp=0.8 at

FE= 37.88 (circles), 39.0 (squares), 40.12 (diamonds),

41.24 (triangle up), and 42.36 (triangle left).

(b) Efficiency NE for the same system at

FE= 37.88 (open circles), 39.0 (filled squares), 40.12 (diamonds),

41.24 (filled triangle up), and 42.36 (triangle left).

(c) Resolution R for the same system at

FE= 37.88 (open circles), 39.0 (filled squares), 40.12 (diamonds),

41.24 (filled triangle up), and 42.36 (triangle left).

(d) Resolution at FE= 40.12 for: (open diamonds)

the system in Fig. 6(a) and

(filled diamonds) the system in Fig. 6(b) where the polymers

were allowed to travel a longer distance.

|